|

|||

|

|

|

|

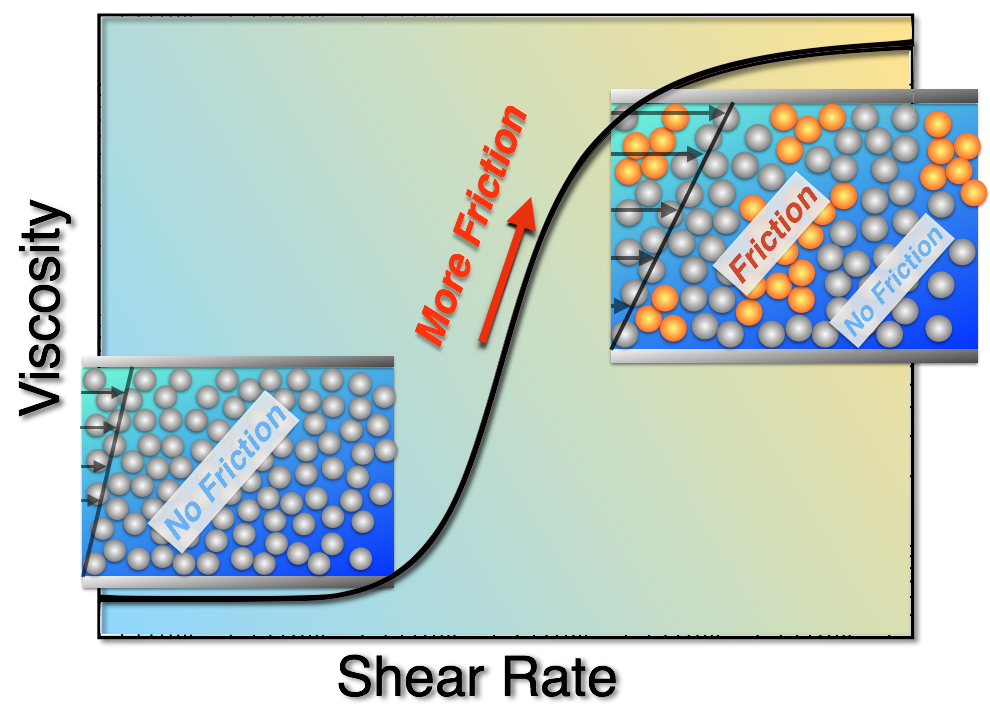

Concentrated suspensions of solid particles frequently exhibit a phenomena known as shear thickening where the fluid's viscosity dramatically increases with increasing shear stress. Shear thickening can be observed in a simple mixture of cornstarch and water, commonly referred to as Oobleck in grade school science demos, and is a crucial consideration in a diverse array of industrial processes, ranging from pouring cement to mixing chocolate. Though easy to observe, despite decades of study the physical mechanism driving shear thickening remains contested, with ongoing debate concerning the role of hydrodynamic interactions and frictional contact forces.

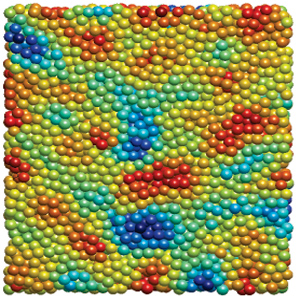

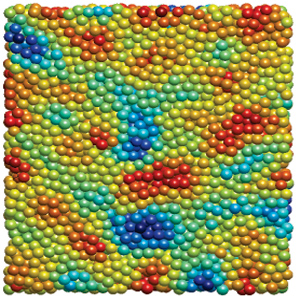

Recent experiments, carried out in collaboration with NIST, exploring both viscous and normal forces in suspensions of colloidal silica spheres shed new light on this debate. These measurements reveal a previously hidden transition in the sign of the 1st Normal Stress Difference, signaling a transition from hydrodynamics-dominated to friction-dominated interactions as the shear thickening becomes more pronounced. This transition demonstrates that shear thickening is driven primarily by frictional contacts, with hydrodynamic forces playing a supporting role at lower concentrations.

These results highlight the critical role of short ranged particle interactions and contact forces in shear thickening suspensions. Ongoing experiments seek to further understand the effects particle size, shape and other surface properties.

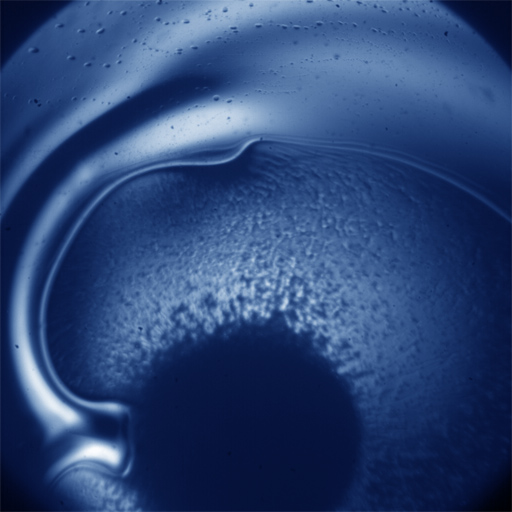

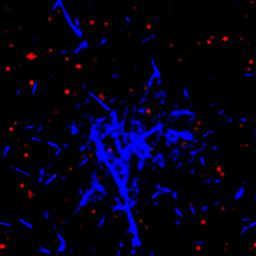

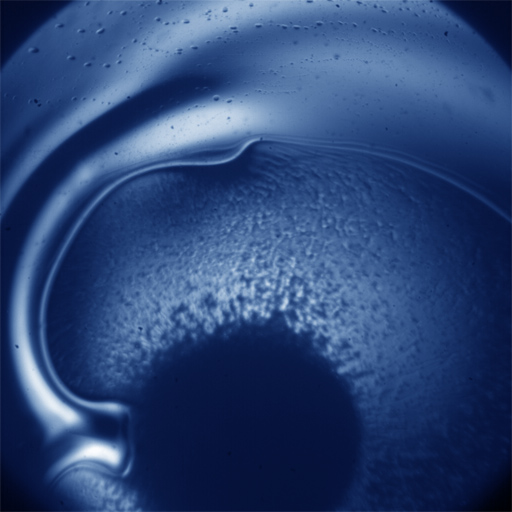

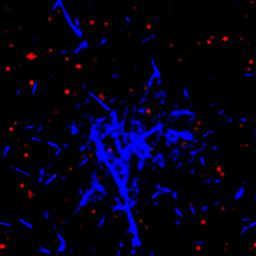

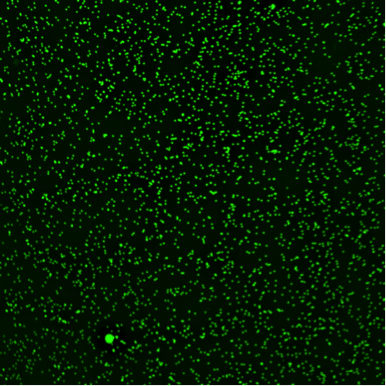

The effects of frictional contacts can be directly observed through the use of Boundary Stress Microscopy (BSM), the displacement of fluorescent beads attached to an elastic substrate are converted into stresses using linear elastic theory. An example of fluorescent 1 micron beads attached to an elastic substrate is shown below.

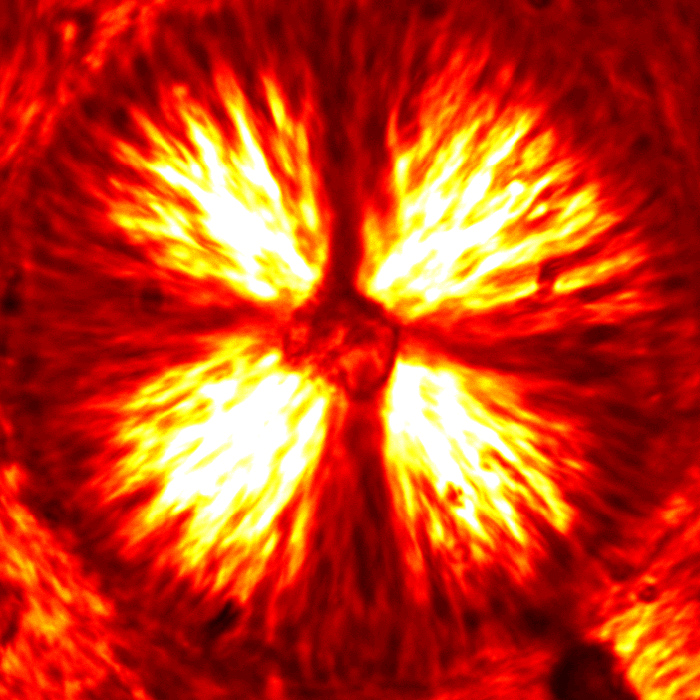

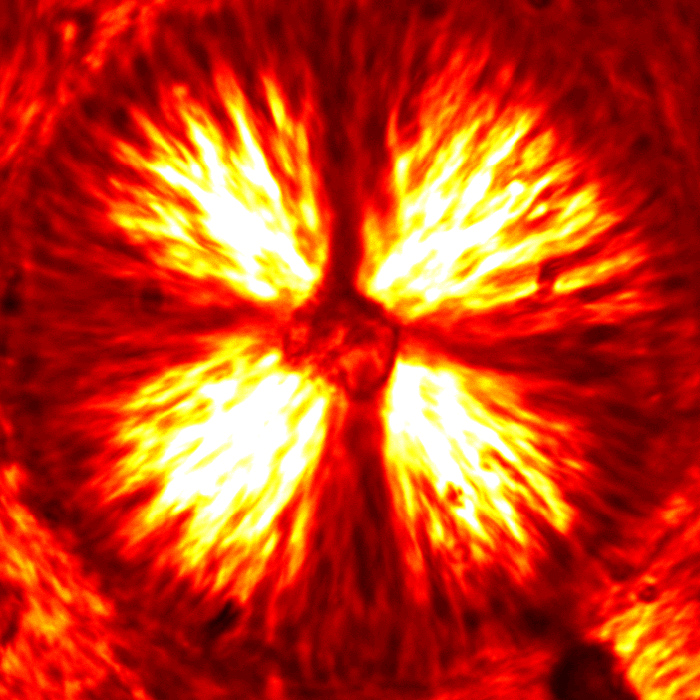

We observe heterogeneous stresses when the applied stress is above the critical value as shown in the image above. The length scale of these heterogeneities is equivalent to the gap size, indicating that a spanning network has formed. These traction stresses are approximately an order of magnitude higher than the applied stress. We observe a growth in magnitude and in number density of these deformations as we apply higher stresses, resulting in a larger viscosity.

These heterogeneous boundary stresses are very dynamic, as can be seen in the video below:

For more information, please contact either John Royer or Vikram Rathee. Additional information can be found at John Royer's website.